THE CASE,this is probably the most overlooked part in any build ,but it is the most important.in my opinion with aftermarket parts being made everywhere and by everyone there is no standard of quality or dimension.the name goes on before the quality goes in .keep that in mind and check everthing 3 times ,because i can garantee the one thing you overlook may be quite costly and frustrating in the end.but don't worrie live and learn and don't do it again.like i said before i figured out what caused my bearing falure so lets get the crank spinning and see if it all makes sence.where to start.

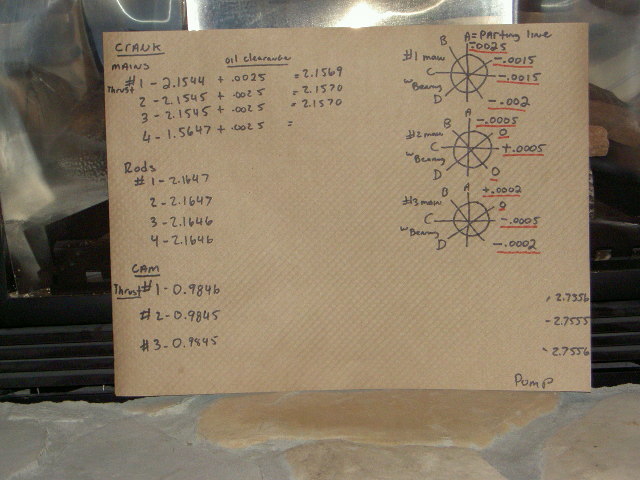

first we need to come up with some kind of dimension.so lets look at the chart .a good radial main bearing oil clearance for a vw motor is between .0025\"-.0030 \"so if we add that to the main bearing size we get 2.1569\" as a target.not deadly important as we are just getting started.

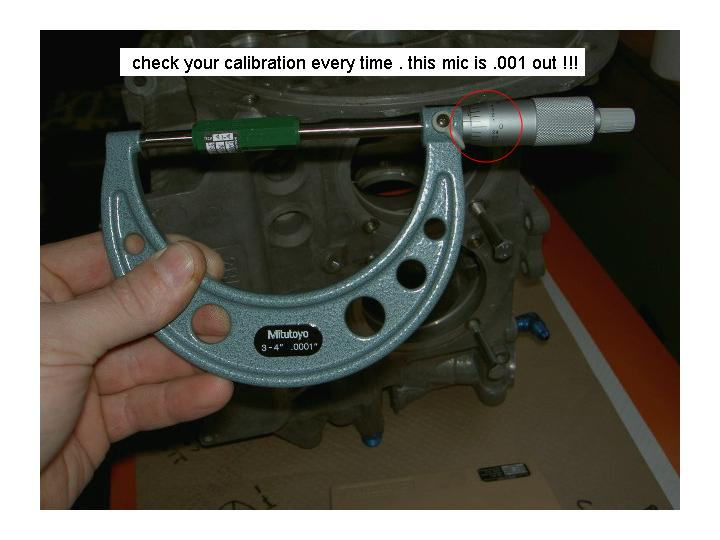

check you equipment,this mic is out .001\"

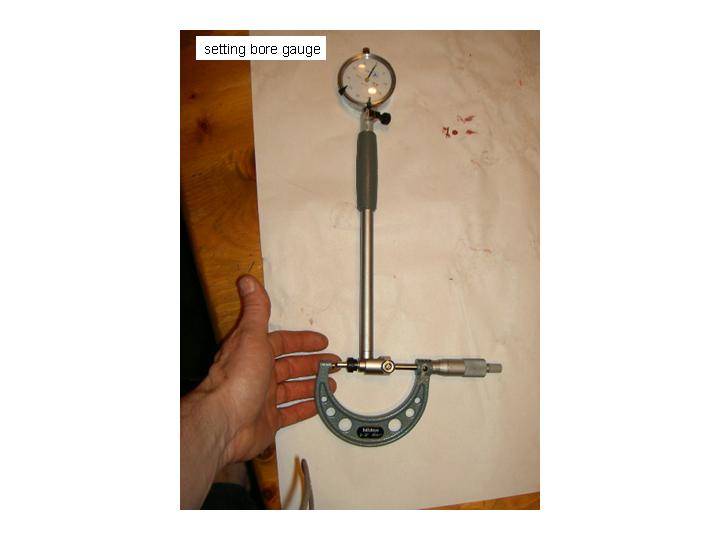

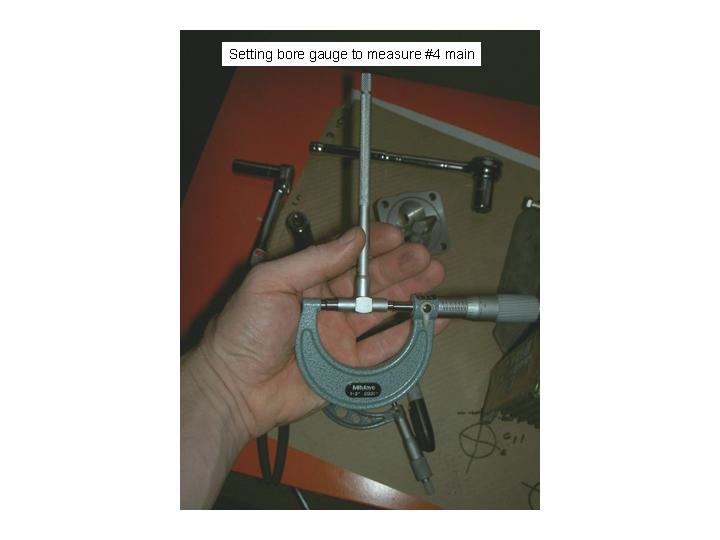

now set your bore guage.first set your mic to the target dimension .2.1569\"then set you bore gauge inbetween the two pads on the mic and rotate the dial to ZERO . you will need to rock the boreguage in the mic to get it dead on.once you try it you will know what i mean.i have made 2 marks one on either side of zero.left is black and right is red.so anything in the black is above the target dimension and anything in the red is less than the target dimension.

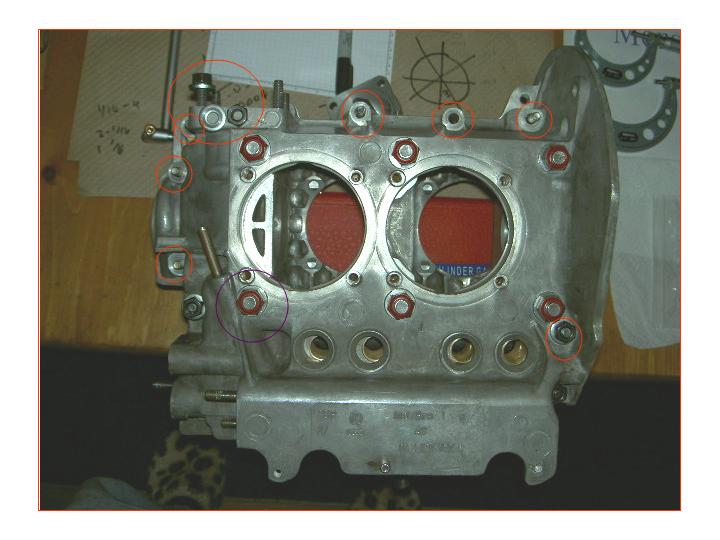

you need to understand that it is impossible to bolt a case together and torque it up and have the bores dead round .the main bearings need to be in the case to alighn the two haves .but you can take some rough measuremnets without bearings to see if the case looks close to specs.those dimensions are in the bently book.after rough measuring mine i new i was in trouble but getting closer to my answer of why my bearing failed.

since i never use the stock #3 bearing i seam to have a endless supplie of them so what i do is load up my case with those.yes #1/2/3 main bores are all the same dimension.

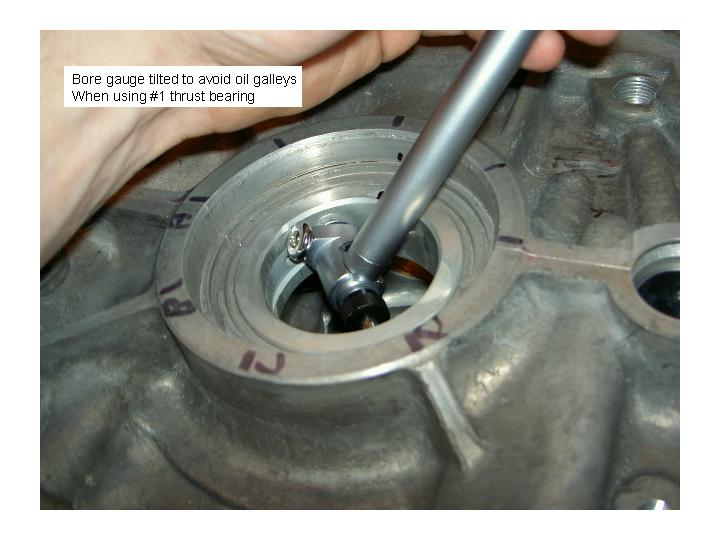

take a look at my # 3 bearing in the #1 bore you can see i marked 2 black area's on the bearing .those are there to remind me to watch out for the oil galleys in the bearing which will upset your measurments.you can also see the locations of measurement points a/b/c/d these are the 4 point i take measurments from remember them as i will refer to them many times.

what was done was to take a measurement at one point .loosen the case and rotate the bearing to the next point ,torque it up and remeasure.this was done for a 4 measurment referance points on all 4 bearings.CASE TORQUE IS HUGE AND WE WILL GET TO THAT LATER.

sound like alot of work but it goes alot quicker than you think.

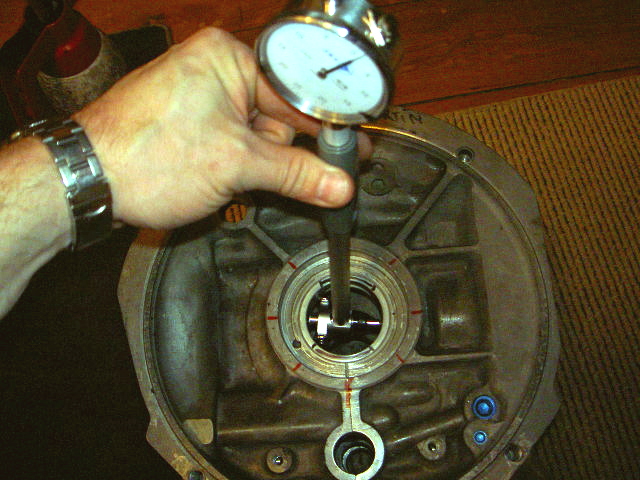

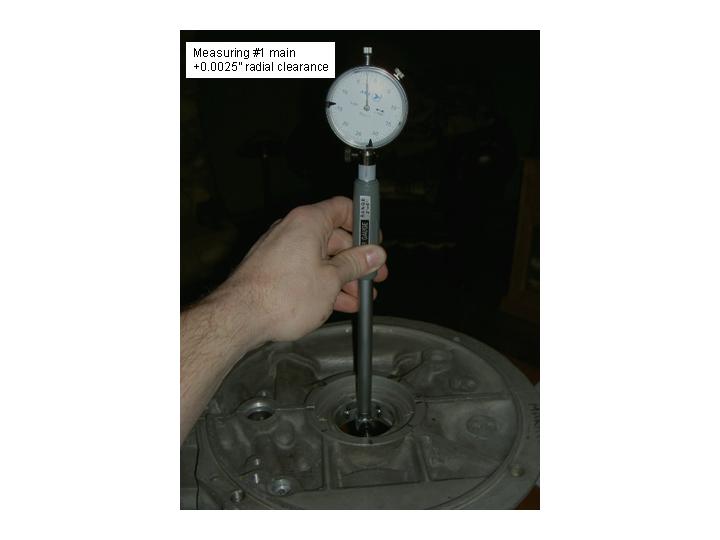

this is how you use a bore gauge ,it is self correcting because the 2 wheels keep it straight and all you have to do is rock it back and forth in the bearing bore and watch the guage .you will figure it out quick once you try one.

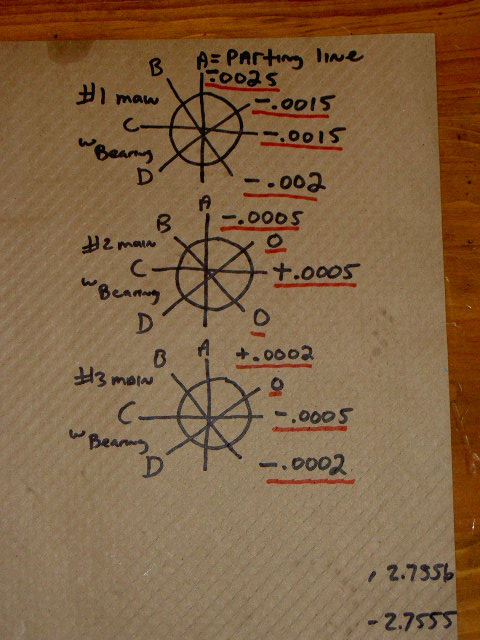

this is what i ended up with

#2 and # 3 mains were almost dead on with less than 0.0005\" out of round !!!.but look at #1 main bearing.you can see that there is in the end no radial clearance.i could not even turn my crank with the case halves just resting together and the crank would be pinched and unable to turn.

this is a better picture of the boregauge in use .don't let your guide wheels fall into the oil galleys,there is a way to do it i will show you later.

i was going to line bore my case myself but i figured i will send it to rocky

at--

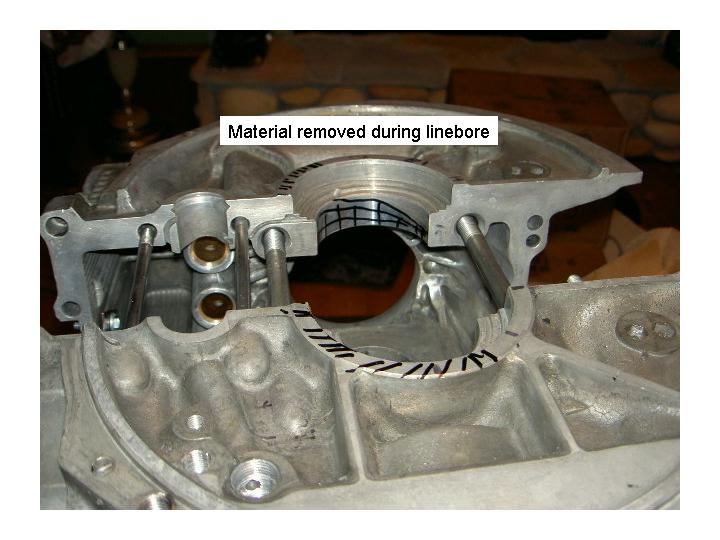

rock jennings-- this guy know his stuff and has a excellent web site,shipping back and forth is cheap as well .under $40.00 cdn to send my case there from vancouver.rocky inspected my case and i told him to make the call.end result rebore to stock dimension #1 main bore only.he eneded up taking out about .0025\" with the cutters set at stock dimension.not bad if i remember that's how much it measured small !!.

take a look you can see the area's in black are where material was removed.

don't think its out of round trust me it's less than .0002\"out.

well with the case back and a quick check with the old #3 bearing in #1 main again it was time to install the main bearing set i would be using.

----missing picture here-------

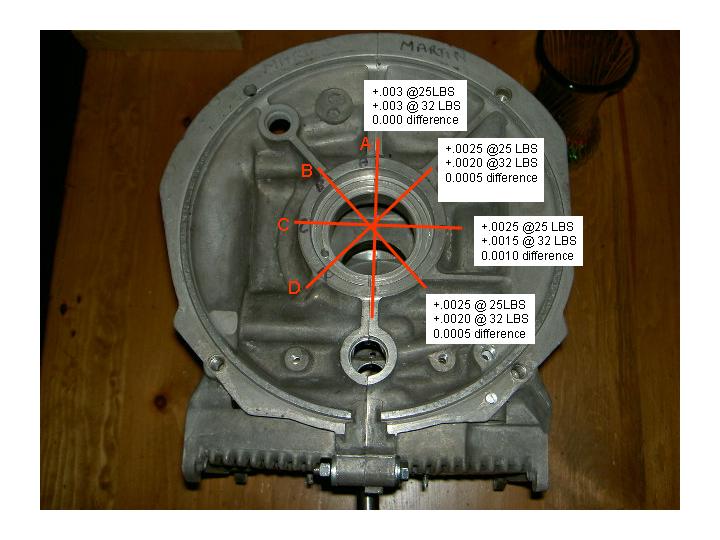

this i found very interesting and added more pieces to my puzzle of bearing falure.with the bore gauge set and case torqued to 25 ft/lbs then later increased to 32 ft/lbs.i took my measurments.but this time as i was using the bearing set i will run in the motor now bearings were not rotated or moved.this is how you sneak past the oil galleys

you can see that the dimension at 'A' parting line of the case does not change.with measuring point 'B' &'D' changing less than .0005\" but at measuring point 'C' there was a differance of .001\" wow!again note this is bearing radial clearance,take note.

i opend the case up and slipped my cam bearings in as well so i could measure them and again torque the case up to 25 ft/lbs on the 6 large nuts.wow!my measurements changed.so i marked them down and retorqued to 32 ft/lbs.take a look the dimension at 'A' stayed the same between the first round of measuring and the second round of measuring but all the other dimensions changed by about .001\" smaller.as well as note the dimensions at both 25 and 32 ft/lbs changed the same amount from the first set of measurements to the second set of measuremnets

maybe the #1 main by desigh is slower to compress than the other bearings.i tryied this again with another new #1 main bearing with almost the same results.can't explain it but take notice that you may want to run your bearing set through a few torque cycles to make sure you get a acurate radial oil clearance.

#1 radial oil clearance 0.0025\"

measuring #2 radial oil clerance 0.0025\"

measuring #3 radial oil clearance 0.003\"

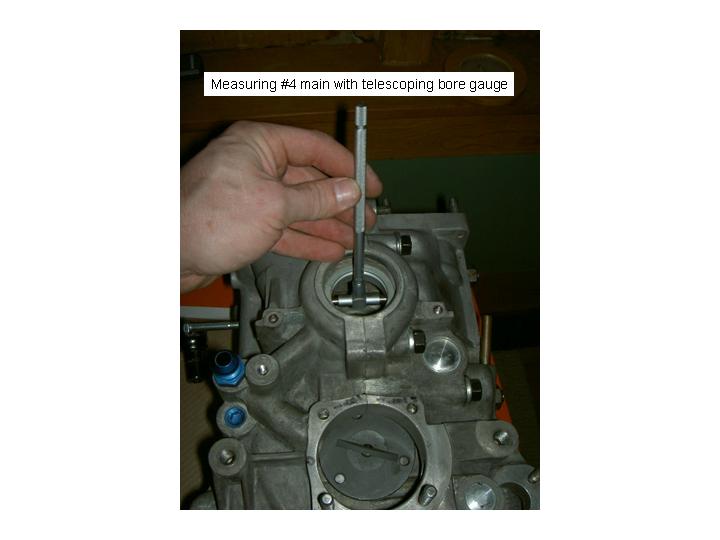

now it's a bit different to measure #4 main radial clearance .but this is what i like to do.first take your crank measurement of 1.5647\" and add say .001\" set your mic to that dimension 1.5657\" and insert your telescoping bore gauge between the two mic pads.and not the drag as you rock the boregauge between the centre point of the mic and remember that feeling

then take your set telescoping bore gauge and go to your case .insert the telescoping bore gauge into the bearing in all 4 positions and roll the gauge back and forth past centre and see if there was any contact.in this case there was not so i will increase another .001\" ,set mic at 1.5667\" and go through the whole procedure again.what i ended up with is a reading of between .0025\" and .0030\"radial oil clearance for th e#4 main bearing which is excellent.that same technic i just described will be used again later .

for kicks and gigles i oiled up all the main bearings and install the crank into the case and torqued it up.and she spins as free as could be !!!!!

--so the three questions are what caused the falure,what has been learned,what is being done to prevent it from happening again.

---the cause? is simple ,first don't believe everthing you read or heard.if you don't have first hand knowledge of something you better learn quick and tripple check everthing if you do it.in the case of my case this is how it goes.i measured out my radial main bearing oil clearance and never checked it again,

but now i know that my #1 main seams to compress a additional .001\" after a couple rounds of torquing.so right off the bat my .0025\" oil clearance dropped to .0015\".as you can see here my case has all the small outside bolts and the 6 inner bolts modified with a gene berg conversion,larger hardware.

these instructions come with the parts and instructions about modifieing your engine case torque to increase case life .sounded good to me so i did it .hey it comes from gene berg so it must be good info.what they don't tell you is that the case deforms when more torque than the factory 25 ft/lbs is applied.that's my fault for not tripple checking that.so you can see by increasing my torque i most likely lost another .001 clearance .so you can see i was running a oval main bore and .0005\" radial clearance.no wonder things seized up.

whats learned ?run bearings through a few torque cycles,don't trust everthing you read or heard,and you can modifie your bearing clearance by modifing your case torque if needed.if you are going to run higher case torque get it linebored torqued to your specs

--prevension, correct measuring of all parts is #1 /modifications to crankshaft end play/ bearings and oil system all which will be covered later.